Services

Providing Innovative Solutions

We welcome the fact that no two businesses are the same, and we love the challenge of tailoring a custom solution that is best for you!

With an open mind and a passion for a challenge, we genuinely want to impress you with the result.

Always cordial and professional, our consultants draw on a wealth of experience to walk with you through the process required to make your vision a reality. You will be provided with your own representative who is on-call to answer your questions and promptly respond to your queries.

We are happy to meet with you on-site at any location, face-to-face and personally assess the project requirements. This will also offer an opportunity to offer potential solutions on the spot, so that we can hit the ground running when we return to our office.

We understand that your investment involves a certain amount of risk and we hope to instil you with confidence in our abilities and trust in us to deliver what we have promised. Working with MayFab should be a stress-free and even enjoyable experience.

MayFab’s in-house designers welcome any challenge and are capable of finding a solution to any problem. All plans are professionally drafted and engineered for your viewing and are compliant with all relevant industry standards.

Drawing on over twenty years of experience, and a continuous state of education and self-improvement, we are well equipped to find the solution to any engineering problem we are faced with.

All manufacturing plans are professionally drafted using 3D CAD (Computer Aided Design) software and any existing equipment is carefully surveyed to ensure all possibilities are considered and accuracy is ensured.

MayFab Engineering offer a Project Management service to assist in effective, planning scheduling and delivery of complex projects. Acting alone or in collaboration with your team, it is our goal to roll-out your project eficciently with as little disruption to your operation as possible.

Delivery plans are prepared and delivered to you prior to installation and we will personally walk you through each step, highlighting any potential risk or implication.

We believe that the key to a successful delivery the is planning. And a successful plan should be seamless and without any surprises.

We can be as involved as you want us to be. If you have a vision but do not know how-to get there, our Project Manager can take over the reigns and keep you updated on the progression of the project.

Our Project Management team can tailor a maintenance, shutdown or project strategy to suit your business needs.

This includes ongoing scheduling and time planning systems in conjunction with your normal business operations.

Our highly skilled tradesmen are will arrive precisely at the nominated time and conduct repairs in a discreet and timely manner. All work is conducted according to safe work practices and will pose no risk to your team and facilities.

Effective planning is especially important when a shutdown of an existing plant is required, and the careful co-ordination of two organisations is required. Because time is money, we do not want to hold up your operation any longer than necessary (if at all).

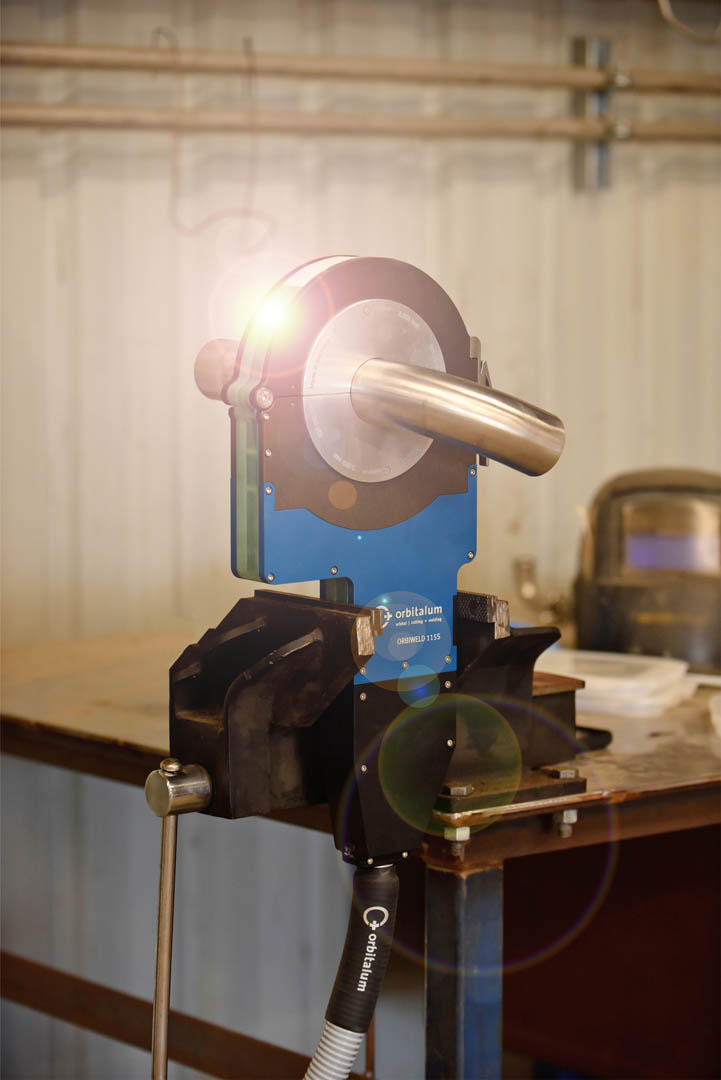

All of our welders have been certified to the highest level (G6) and fabricate in compliance with AS 4041 – Pressure Piping and AS 1554 – Structural Steel Welding. All of our work goes through a rigorous quality assurance system ensuring the best result – every time.

She scope of fabrication work we can undertake is very broad as we make sure that we are aware of and trained in all modern forms of steel fabrication.

Our large workshop located in Barmera SA is well equipped for a wide variety of steel fabrication tasks including a Siegmund Jigging Bench for mass production, specialised GF Pipe Cutters for cutting up to 8″ pipe, 135tonne Break Press Guillotine, the latest 400amp Cold Wire Feed TIG Machine from Lorch Technology, and many other forms of steel fabrication equipment

We are capable of undertaking remote work off-site no matter the location or time of the day. It is our responsibility to bring all required equipment with us an arrange accommodation as required to get the job done.

We have on-hand, a variety of portable welding units depending on the grade of steel to be operated on. And to round our off-site capabilities we have a 4 tonne JCB Telehandler with a 17m reach, allowing us to conduct high elevation work even on unsurfaced or uneven terrain.

Whether it is an emergency response, or a planned repair at a remote location, we are here to keep you running.

Projects

Making your project flow

MayFab Engineering provides steel fabrication, engineering, design and consultation services to customers requiring medium to large-scale industrial pipework across Australia.

Working on

Additional Services

OIL & GAS SUPPLY

Pipework in the oil and gas industry, require a particularly high level of care to ensure the security of this volatile resource and the safety of those in close contact with it.

WATER INFRASTRUCTURE

Pipe spoiling fabrication is the most common requirement of the water management industry. Often, custom fabrications are required to connect a new pump to old infrastructure.

FOOD & WINE PROCESSING

We provide a wide range of equipment installation and maintenance services including fixed-line key stations and the commissioning of centrifuges and cross-flows.

TANK FARMS

No job is too big, we specialise in tank farm installation and related pipework systems. We are equipped and licenced for high risk work as required.

REFRIGERATION & HEATING

We are able to perform certified and coded welding of steam and ammonia high-pressure pipework. Other services include installation and replacements of valves and condensers.

STRUCTURAL STEEL

Nothing is out of the question. We even undertake mild steel structural work such as fixed platforms, railing, walkways, stairways, and ladders for industrial buildings.

Our Location

Quick contact

We are open Monday to Friday

7:30am – 4:00pm and are looking forward to starting your next project.

Quality

We implement a nationally recognised best practice approach to our business, from how we conduct ourselves, to the care we take in design, to the work we produce.

Reliability

Effective project management is integral to every project we undertake, ensuring each project we undertake is delivered on time, every time.

Experience

With more than twenty years in the industry, MayFab provides the peace of mind that you have engaged a "well-oiled machine" to deliver on your project.

Knowledge

We are in a constant state of learning - in regard to the latest technology available, the best techniques in practice and ongoing changes to regulations and qualifications.